INVESTMENT CASTING SAND CASTING STELL RAILING & PIPE FITTING PRECISION TURNED COMPONENTS ALUMINIUM PRESSUR DIE CASTINGBRASS CASTINGElectric Transmission PartsWater Meter

|

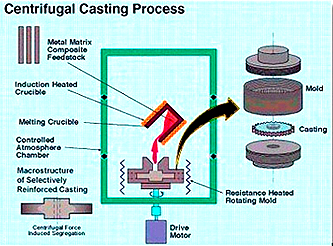

This process can be categorized as similar to that of permanent mold method. Here as the molten metal is being poured, a permanent metal mold revolves about its axis at high speeds ranging from 300 to 3000 rpm. This can be in horizontal, vertical or inclined positions. As a result, the molten metal is centrifugally thrown towards the inside mold wall. There it solidifies after cooling. It's usually a fine grain casting with a very fine-grained outer diameter.

The mold is preheated before coating, so as to dry the coating and improve the adherence to the mold surface. In the metal flask a predetermined mass of refractory material in slurry form is poured. The flask on rotation makes the refractory materials centrifuged onto the wall of the flask. The rotation is stopped and the liquid portion of the slurry drained off. It leaves the mold with a refractory coating, to be baked until dry before use. Features of Centrifugal Casting :

Applications of Centrifugal Casting : |